About us

History

Wiedenmann GmbH was founded in 1964 by Gertrud and Georg Wiedenmann.Consistancy and reliability have been the company’s philosophy from the very beginning and the basis of its guiding principle” only the best”. This philosophy has enabled the company to grow into one of the leading companies in the field of turf maintenance.

1964

Company foundationGertrud and Georg Wiedenmann establish the company Wiedenmann GmbH with headquarters in Rammingen. Starting off with 4 employees.

1974

Purchase of WIMA BruchsalThe young company takes over the insolvent company Raible, manufacturer of sweepers and rake blades in Untergrombach near Bruchsal. — A bold decision after only a short time in business —

1975

100th employeeIn 1975 the number of employees exceeds 100 for the first time.

1980

Wiedenmann FranceThe sales company Wiedenmann France is established.

1981

Start NC TechnologyThe first controlled production machine is a TRUMPF nibbling machine.

1985

Entry H. WiedenmannThe first of 3 sons, Horst Wiedenmann, enters the family business in the area of Production and Technology.

1985

Wiedenmann sweeping-mobileThe construction of the sweeping machine is a first step into the world of self-propelling machines.

1985

Building the "L" hallThe new building of generous dimensions ("Schwörer building") provides space for the new NC machines as well as the areas of assembly, distribution and spare parts warehouse.

1986

Entry J. WiedenmannA year later, Jürgen Wiedenmann follows in his brother's footsteps in the area of Sales and Administration.

1988

Internationalisation of SalesNew paths in the Sales division start the systematic development of the European and international sales network.

1989

Introduction of 2D CAD SystemThe introduction of the Autocad 2D construction system represents another important structural step.

1990

Developing the area of ConstructionThe area of Product Development is increasingly modernised. If, up to this point in time, product development had largely followed a "hands-on" approach, now is the time to build more conventional Construction and Development divisions.

1991

British golf market is developedTogether with partner Wiedenmann UK, the British golf market is developed — a milestone in export—

1991

Wiedenmann TERRA SPIKEA success story begins. With the TERRA SPIKE, the first deep fan is manufactured.

1992

New powder lacqueringThe new technology at the time, "powder coating", is introduced.

1992

Acquisition of Wiedenmann KFTAs early as 1991, the first cooperation with BMG, a state-owned company at the time, takes place in Beled / West-Hungary. In 1992, 100% take-over and development into a manufacturing location for WDM and WIMA.

1993

Wiedenmann Multi-MobileIn 1993, the Multi-Mobile replaces the Sweeping-Mobile of ´89 . There will be no further "jaunts" into the area of self-propelled machines but these two. Once production of the Multi Mobile is discontinued, the "world of attachment devices" in the tractor range from 20 to 60 hp will become the strategic core competency of Wiedenmann GmbH.

1993

200th employeeIn 1993, 200 employees are employed at 3 locations.

1993

Initiating OEM productsIncreasing levels of recognition and success across Europe are opening up new business opportunities. With the vacuum MCS 345H for John Deere, the first "Wiedenmann OEM" comes on the market. Over the years, further products for other original equipment manufacturers such as Kubota, Hako, Aebi are to follow.

1994

Laser technologyIn the area of Production, investments in laser cutting technology make progressive construction and manufacturing possible.

1994

Export successFor the first time, export shares exceed the 50% threshold.

2000

Entry U. WiedenmannThe youngest son, Uwe Wiedenmann follows his brothers into the company in the area of Acquisition.

2000

Foundation of Wiedenmann NAIn order to get a foothold in the American market, a "bridgehead" in form of a Sales subsidiary in the south-east of the US is established with Wiedenmann North America in October 2000.

2002

Setting up a service areaIn late 2002, development in the area of (application) technological support for importers and dealers begins.

2002

Centralising the SalesIn line with the continuously increasing focus on export, the Sales activities of WIMA and Wiedenmann GmbH are merged - Objective: a central customer contact partner for the entire product range.

2003

The 2nd generation takes over14 July 2003: The 3 sons take over the parental business together.

2004

New construction warehouseThe new construction of a finished goods warehouse creates the urgently needed space for further growth.

2004

Integration WIMAIn the context of a further centralization and streamlining of the product range, the decision was made to integrate the Bruchsal site into the main site in Rammingen.

2005

New construction shippingThe shipping area will be completely redesigned after completion of the new finished goods warehouse.

2006

Export as an engineWithin the last 8 years Wiedenmann has tripled its turnover. tripled. The export goes to more than 35 countries of the world. The export share in the turnover exceeds the 70% limit.

2007

New office buildingThrough new construction and remodeling, administration, purchasing and AV are centrally located in one building. Short distances - improved communication is the goal.

2010

PC network conversionCentral server farm at the Rammingen site consolidates all PC applications. Introduction of MS Outlook as the future communication platform, conversion of the Beled site to terminal server technology. - Creation of the necessary prerequisites for the progressive digitalisation of business processes.

2011

Wiedenmann Internet PartsAt the end of 2010 / beginning of 2011, the internet shop solution for spare parts orders will go online. Further expansion stages will follow. — Another building block of customer appreciation —

2013

New powder painting plantA new painting plant was put into operation to achieve an even better paint quality and a more environmentally friendly painting process.

2014

50 years WiedenmannWiedenmann GmbH celebrates 50th company anniversary.

2016

25 years of Terra SpikeA success story begins. In 1991, the first deep aerator is manufactured.

2018

New machining centre in RammingenEstablishment of a mechanical production facility at the Rammingen site with its own welding robot and a milling machine with a bed size of 4x1.5 m.

2018

Football World Cup in RussiaWiedenmann turf maintenance machines are used in 10 out of 12 World Cup stadiums.

2020

Resignation J. WiedenmannJürgen Wiedenmann retires from the company as operational managing director.

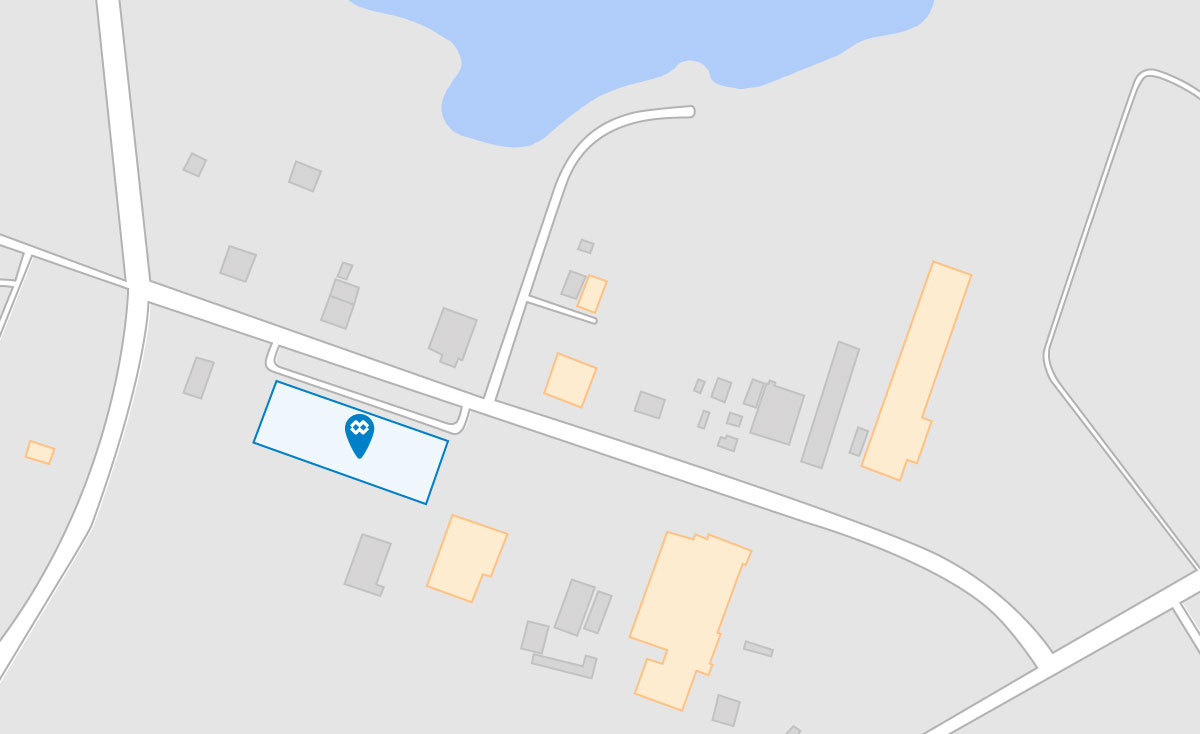

locations

Am Bahnhof

89192 Rammingen

Germany

Tel. +49 (0) 73 45 / 953-0

Fax +49 (0) 73 45 / 953-233

info@wiedenmann.de

Rákóczi u.228

9343 Beled

Hungary

Tel. +36 96 594 120

Fax +36 96 594 128

info@wiedenmann.hu

25A Telfair Place

Savannah, GA 31415

USA

Phone 912-790-3004

info@wiedenmannusa.com

Ideas for tomorrow. With the know-how of today.

Innovation already begins in the development phase. This is why our engineers exclusively use state-of-the-art 3D-CAD technology to exclude any possible weak points in the development process. Changes in the form or parts can be made without manufacturing expensive samples. Dimension accuracy up to a thousandth of a millimetre, and the ability to rapidly create and modify drawings are additional advantages of this design method.

This decisively reduces the development time and costs of a new product, resulting in a less expensive sales price for you. Every new development must prove itself in a long test phase of extensive and rough practical trials, and they must meet the development target to one hundred per cent. Only then will they be released for production. Each machine is carefully assembled to meet specific customer requirements.

Then an intensive final inspection is conducted. Finally, every machine is packed for safe transport and prepared for on-time shipment to the customer. As a manufacturer of machinery for turf maintenance and municipal services, we feel particularly responsible for using environmentally friendly production processes. We do justice to increasing demands for the lowest possible levels of environmental pollution with our semi-automatic blasting system. The cleaned surface provides the optimum basis for subsequent coating processes. The prepared parts are subsequently painted by powder coating. Electrostatically charged coloured powder particles are sprayed on and burned in at about 220 °C.

Our Team

Our Team – as diverse as the seasons

The Team of the Wiedenmann GmbH: Whether spring, summer, autumn or winter – whether professional turf and golf course maintenance, dirt clearance or snow removal services: you can rely on the team from Wiedenmann in every season.

True to our guiding principle “Only the best for the customer”, a competent team in internal sales, field sales, service and development is there at your disposal.

As one of the world-wide leading manufacturers, our approximately 245 employees in the German town of Rammingen near Ulm as well as in the Hungarian town of Beled regularly set new standards of innovative technologies and uncompromising quality. Numerous innovation prizes, patents and proprietary rights testify the high-performance expectations of the family-owned company founded in 1964. With a far-sighted vision, we continually invest a substantial part of our annual turnover in research and development.

By attending diverse trainings, coachings and courses we pay particular attention to the continious development of our team to ensure that today we can already offer you the solutions of tomorrow.

Also our students and apprentices are supported and challenged in learning projekts, in order to encourage self responsibilty, communicational skills and creativity. Beside a extensive operational know-how these are core capabilities to be able to take over core positions in our company.

We look forward to working with you and demonstrating our expertise and reliability as your partner.

Corporate Culture

Wiedenmann GMBH is working actively since several years to form its corporate culture. This concerns amongst other themes transparency, team spirit, loyality, but also failure culture and willingness to change of both, employees and leaders.

The wide range of challenges, – in view of current social, economic, and cultural trends -, which the small to medium sized enterprises are confronted with today and in future, can only be mastered by a “work community”, which is willing to change, learn and mutually form the organizational culture.

In the medium to long term, we aim therefore to achieve a self learning organization, which by distributed leadership and the gained change and development competence is well prepared for the challenges and trends to come.

Regular 2 day workshops, gathering participants from different levels of hierarchy and knowlegde areas, contributes to this goals in the same way as coaching for leaders and the support of an open and reliable communication.