Innovative snow blades

Wiedenmann fills with bio-hydraulic oil

Winter service is becoming greener: for the first time, German manufacturer Wiedenmann is offering its snow plough blades with biodegradable hydraulic oil. This is intended to reduce the environmental impact of winter services provided by local authorities and contractors – a challenge that required expertise.

The use of snow ploughs is essential for clearing snow and ice from roads and paths. Even in winters with little snow, the equipment must be in perfect condition and ready for operation. However, in the event of a defect, they can have a major impact on the environment: hydraulic oil in particular, which is contained in large quantities in the control and lifting systems, can be very problematic for the environment.

Unfortunately, the operational profile of the equipment increases the risk of leakage, as the shields are usually only in operation for a few hours a day, and only in winter. The hydraulic oils therefore remain in the cylinders and lines for a long time and are exposed to fluctuating temperatures.

Technically demanding

‘Switching to a biodegradable hydraulic oil is more complex than it seems at first glance,’ explains Volker Zippel, Product Manager at Wiedenmann. ‘Not every oil is suitable for all shield components.’

The main challenge lies in material compatibility. Seals, hoses and valves must be able to withstand the new oil without being impaired in their function. Biodegradable oils have different chemical properties, for example a different viscosity, which can increase wear on certain parts.

‘We worked closely with our suppliers to put all components and hydraulic systems through their paces.’ This was not only time-consuming, but also required extensive performance and endurance tests. The changeover was successful with a fully synthetic and zinc-free oil based on saturated esters. It scores particularly well in terms of oxidation stability, wear protection and viscosity behaviour over a wide temperature range.

A step towards greater sustainability

Initial feedback from local authorities and operators has been positive. A major order for 20 shields was also placed straight away. Customers welcomed the ecological innovation, especially as they are in the public eye more than ever in times of increasing environmental regulations and want to be technologically prepared, says Zippel. One of the first snow blades with the new bio-oil is the Vario 3359 with a blade width of 150 cm. Further information can be found at Wiedenmann.de.

(2) Download:

This PR complete with photos and addresses

Selection of photos:

https://www.pressways.de/service/wiedenmannraupenschild.jpg

https://www.pressways.de/service/wiedenmannschildherbst.jpg

https://www.pressways.de/service/wiedenmannvarioflexschnee.jpg

Caption: Clearing blade from Wiedenmann’s Vario series: Now for the first time with biodegradable hydraulic oil (Photo: Wiedenmann).

Selection of product photos optional:

https://www.pressways.de/service/wiedenmannvario.jpg

https://www.pressways.de/service/wiedenmannvarioflexfrei.jpg

Caption: Vario Flex plough blade from Wiedenmann (Photo: Wiedenmann).

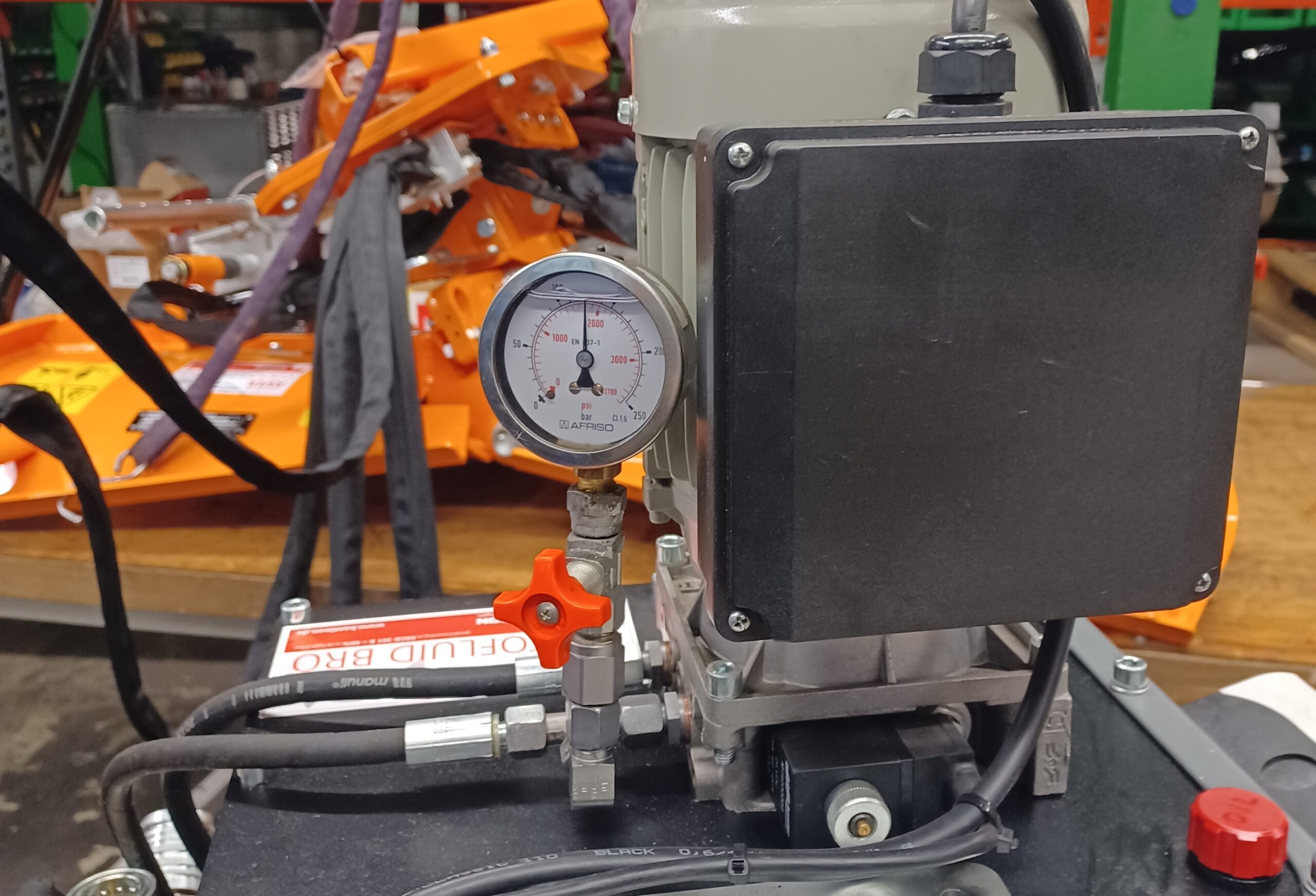

https://www.pressways.de/service/wiedenmannschildkontrolle.jpg

Caption: Is the oil pressure correct? Final inspection of a Snow Master Vario plough blade with new bio-oil at Wiedenmann in Rammingen (Photo: Wiedenmann).

(3) Contact person:

Author, editorial contact and specimen copy

Wiedenmann press office

Mr Björn Hoffmann

Phone +49 (0)521 – 260 2513

Mail wiedenmann@pressways.de

Pressways PR, Ecos Office Centre

Herforder Str. 69, D-33602 Bielefeld

Contact person in the company

Mrs Verena Schäch

Wiedenmann GmbH

D-89192 Rammingen

Tel 07345 – 9530

Fax 07345 – 953233

Internet www.wiedenmann.com

Galerie